1/89 Stanley Rd, Ingleburn NSW 2565

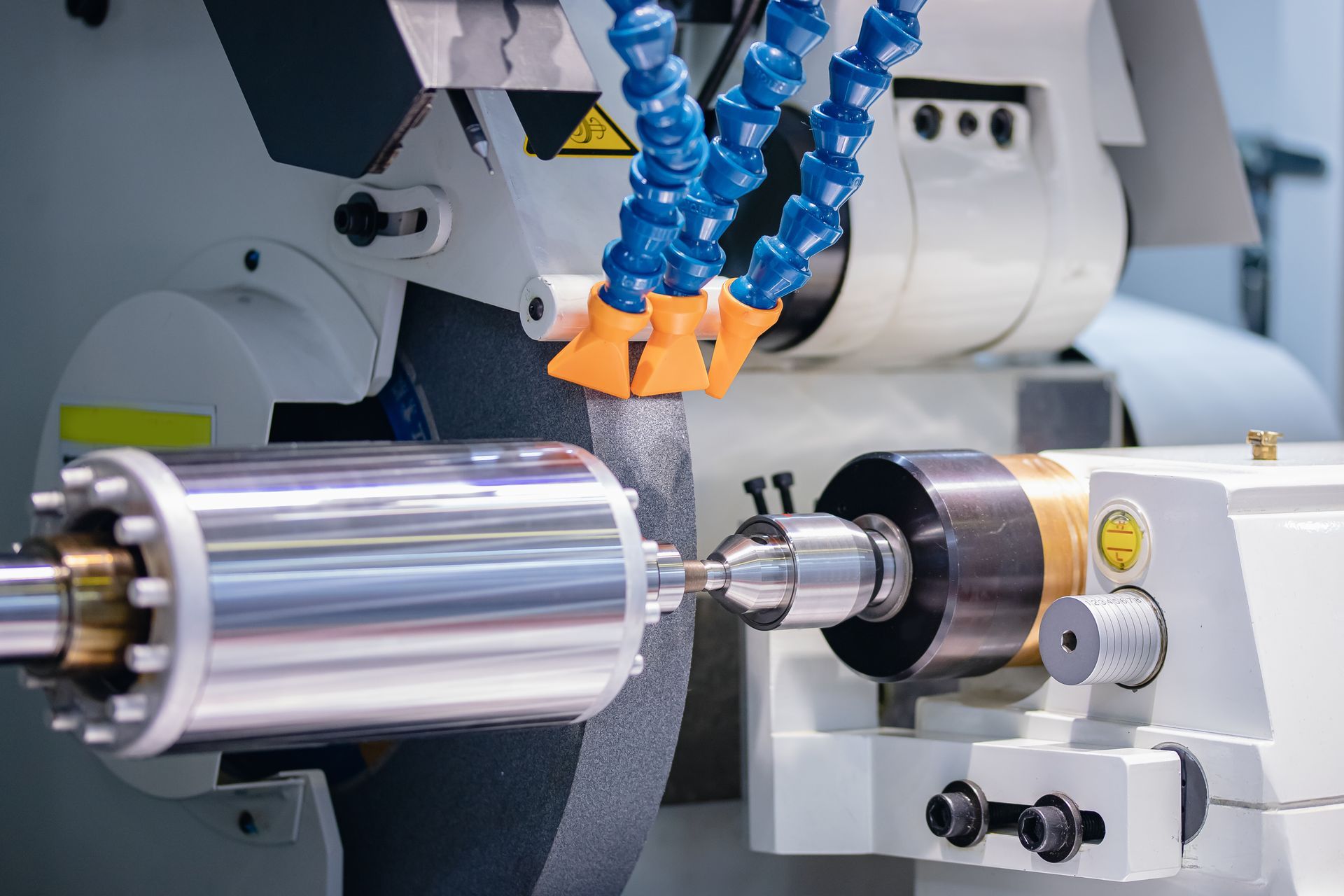

CNC Turning

Get high-precision, high-quality custom turned parts for your project at a cost-effective price that works with your budget. Be it for prototyping or mass production, CNC Precision Machining offers the ideal solution for your CNC turning needs.

High-Quality CNC Turning Service

CNC Precision Machining is your go-to partner for CNC turning services, crucial for crafting items with rotational symmetry, from shafts and pulleys to valves and flanges. Our advanced CNC turning machines, operated by expert engineers, ensure the production of identical parts with tight tolerances.

Partnering with us means leveraging cutting-edge technology, extensive industry knowledge, and a commitment to precision and efficiency in transforming your concepts into reality.

In CNC machining, the choice between turning and milling depends on factors like part geometry, material properties, production volume, and machining complexity. Get in touch to discuss your project.

Components Crafted through CNC Turning

- Rollers: CNC lathes adeptly fabricate rollers with precise tolerances for various industrial applications.

- Ball Joints: CNC turning is the method of choice for crafting rounded connective devices like ball joints.

- Nuts and Bolts: The accuracy inherent in turning makes it an ideal process for manufacturing tolerance-critical items such as nuts and bolts.

- Shafts: CNC turning excels in producing shafts with rounded profiles.

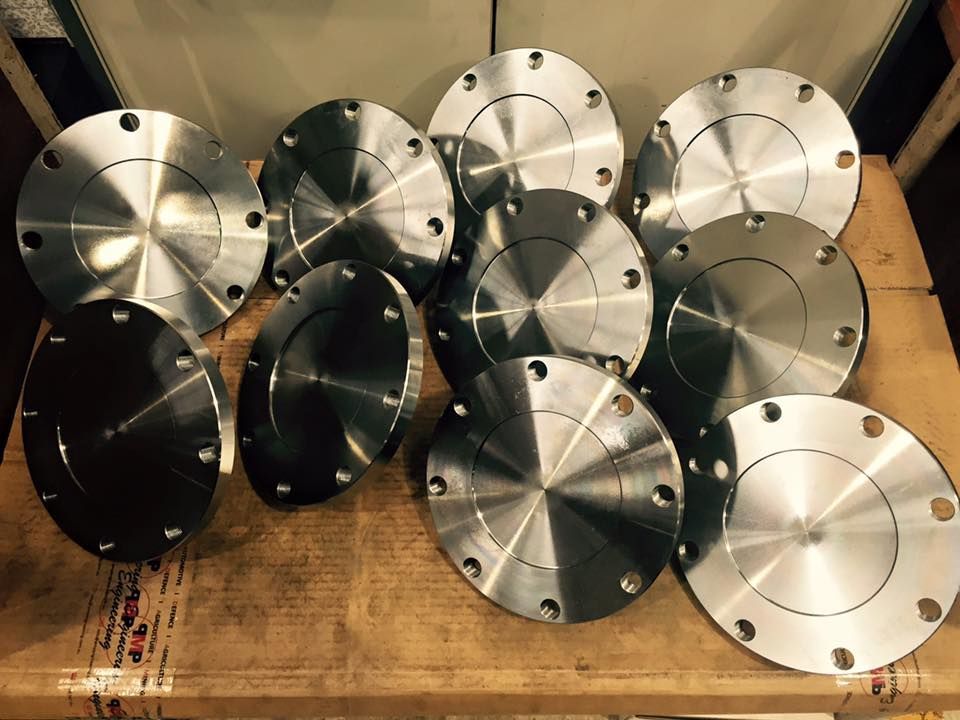

- Flanges: CNC-turned flanges serve to reinforce beams and pipes with precision.

- Nozzles: Typically cylindrical or conical with hollow insides, nozzles are well-suited for CNC turning.

- Turbines: CNC turning is instrumental in creating round turbine blades for applications in the energy industry.

Materials We Work On

Metal

- Aluminium

- Steel

- Stainless steel

- Brass

- Copper

- Titanium

- Mild steel

- Alloy steel

- Tool steel

- Spring steel

Plastic

- ABS

- Polycarbonate (PC)

- Nylon

- Polypropylene (PP)

- POM

- PTFE (Teflon)

- PMMA (Acrylic)

- Polyethylene (PE)

- PEEK

- Bakelite

- FR4

- Rubber

If the specific material you are seeking is not listed, we encourage you to reach out to us as we might be able to work on it.

Our CNC Milling Capabilities

Barfed

- Programmed and operated by 1st class tradesman

- Programmed with CADCAM software;

- Topsolid

- AutoCAD

- Gibbscam

- Or direct on the conversational control

- Capacity 600mm dia x 1500mm long

Labourer Operated

5 CNC Lathes

- Programmed and operated by 1st class tradesman

- Programmed with CADCAM software;

- Topsolid

- AutoCAD

- Gibbscam

- Or direct on the conversational control

- Capacity 600mm dia x 1500mm long

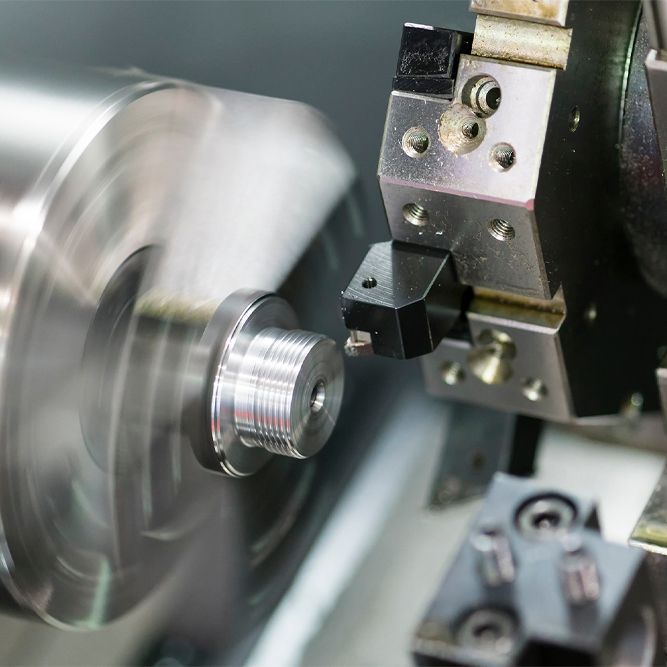

CNC Lathes

Machines range in size and capability

- Robot-loaded, barfed and manually loaded

- Programmed with CADCAM software

- Programmed and operated by 1st class tradesman

- AutoCAD

- Topsolid

- Gibbscam

- Or direct on the conversational control

- Single & Twin Chuck

- Prototype through to production

Advantages of CNC Turning Over Conventional Methods

Our Proficiency is Your Strategic Advantage

Please don't hesitate to reach out with any enquiries or questions you may have regarding our services. Our team is here to provide you with the information you need to explore how we can assist in the development of your new product or process.