1/89 Stanley Rd, Ingleburn NSW 2565

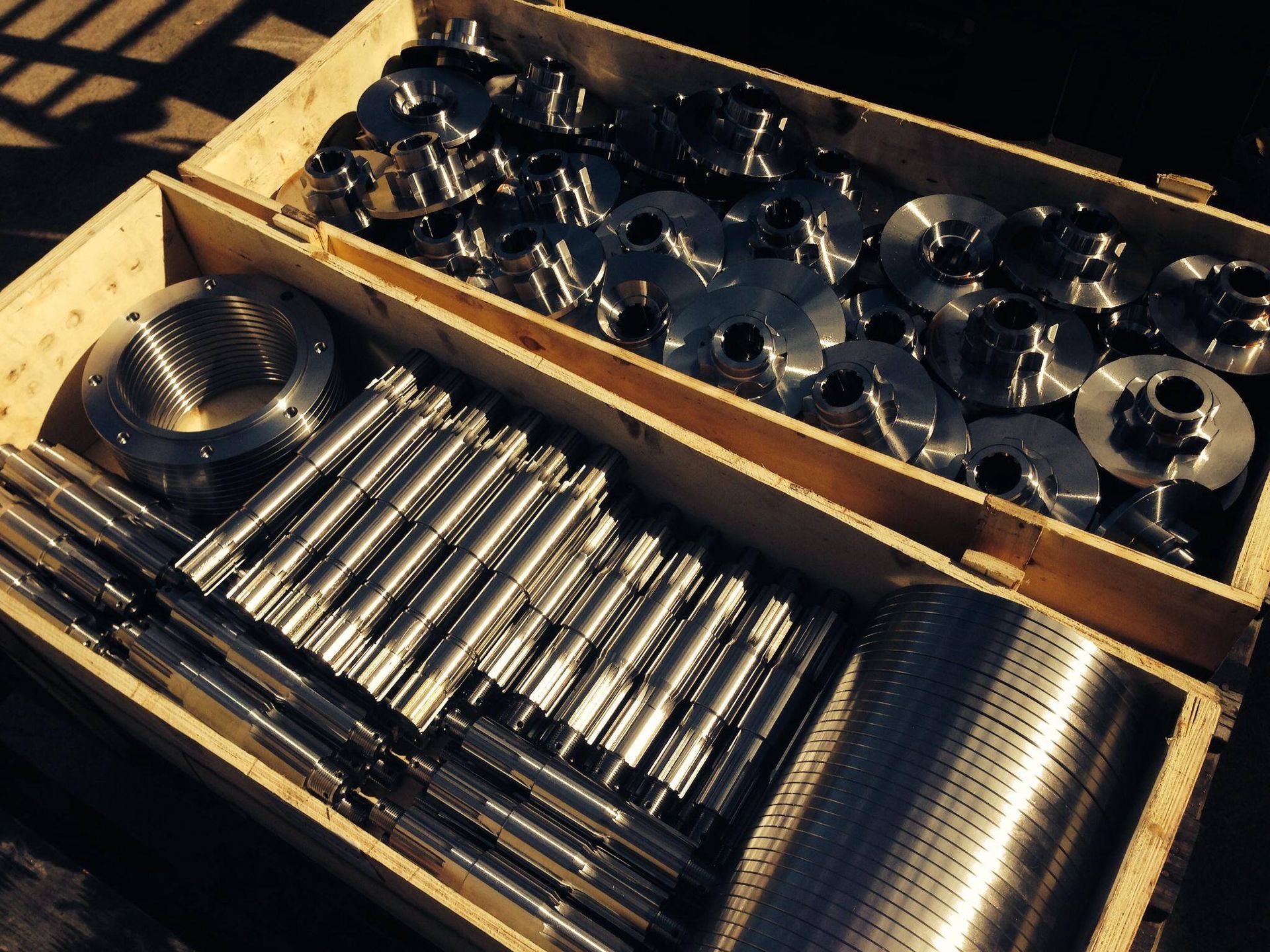

Conventional Machining (Non-CNC) Services

Get your parts produced using conventional machining processes. Ideal for small batches and one-offs for prototyping and end-use components.

Expert Conventional Machining Service

Our traditional machining process involves skilled operators guiding tools like milling machines, lathes and drills.

CNC Precision Machining boasts a fully equipped conventional machine shop capable of handling prototypes and small production volumes. Our adept tradesmen, paired with reliable traditional machining equipment, guarantee precise craftsmanship and high-quality production at a cost-effective price. This offers the reliability and flexibility necessary for your distinctive manufacturing needs.

In machining, the choice between conventional, CNC turning and CNC milling depends on factors like part geometry, material properties, production volume, and machining complexity. Contact us to discuss your project.

Materials We Work On

Metal

- Aluminium

- Steel

- Stainless steel

- Brass

- Copper

- Titanium

- Mild steel

- Alloy steel

- Tool steel

- Spring steel

Plastic

- ABS

- Polycarbonate (PC)

- Nylon

- Polypropylene (PP)

- POM

- PTFE (Teflon)

- PMMA (Acrylic)

- Polyethylene (PE)

- PEEK

- Bakelite

- FR4

- Rubber

If the specific material you are seeking is not listed, we encourage you to reach out to us as we might be able to work on it.

Our Non-CNC Machining Capabilities

Conventional Lathes

- 600mm diameter x 2000mm long

- Operated by 1st class tradesman

Conventional Mills

- Bridgeport

- Operated by 1st class tradesman

Bandsaw

- 250mm diameter

Other

- Gear Cutting

- Splining

- Horizontal Broaching

Advantages of Conventional Machining

While CNC machining provides a number of very significant benefits such as advanced precision and automation, there are specific scenarios where opting for conventional machining proves advantageous.

Our Proficiency is Your Strategic Advantage

Please don't hesitate to reach out with any enquiries or questions you may have regarding our services. Our team is here to provide you with the information you need to explore how we can assist in the development of your new product or process.